A blank wall is a lost chance—but the correct cladding can transform everything. That’s where E3 Aluminium Composite Panels come into play, with style, power, and intelligent pricing. But what specifically makes it worth every cent?

If you’re looking for the best aluminium composite panel price without sacrificing quality, E3 gets you exactly that. Renowned for its high-end finishes and enduring performance, we have become an architect and homeowner favorite.

Here, in this blog, we discuss why the E3 ACP sheet rate is not only reasonable, but it’s an investment in style and longevity. Whether you are designing a new building or renovating your property, let’s discover what makes the E3 every dollar spent worthwhile.

What are ACP Panels?

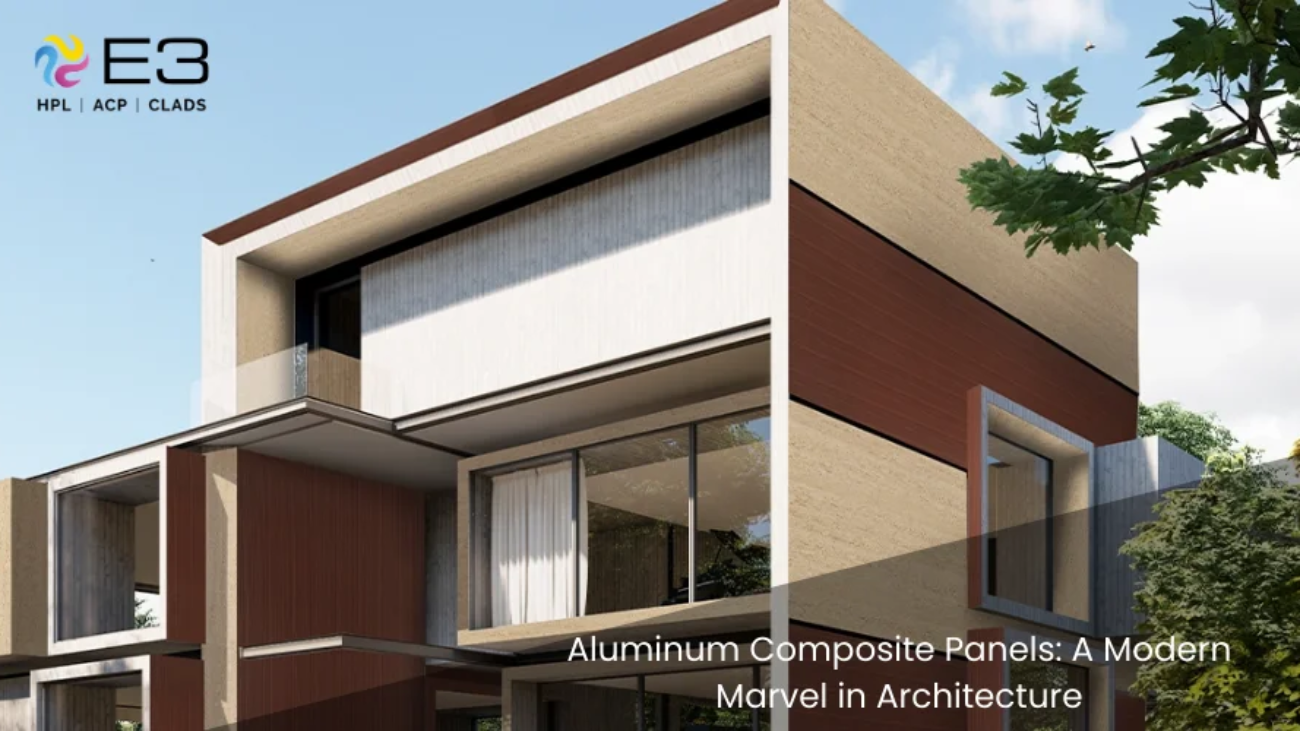

An ACP panel is a flat panel consisting of two thin aluminium sheets bonded to a non-aluminium core, typically constructed from polyethylene or a fire-retardant core. Being known for their hardness, lightness, and smooth surface, ACP sheets have emerged as a popular building material in contemporary architecture. Generally, aluminium composite panel price depends on many factors. Their durability and flexibility make them suitable for use in a variety of structural and aesthetic functions.

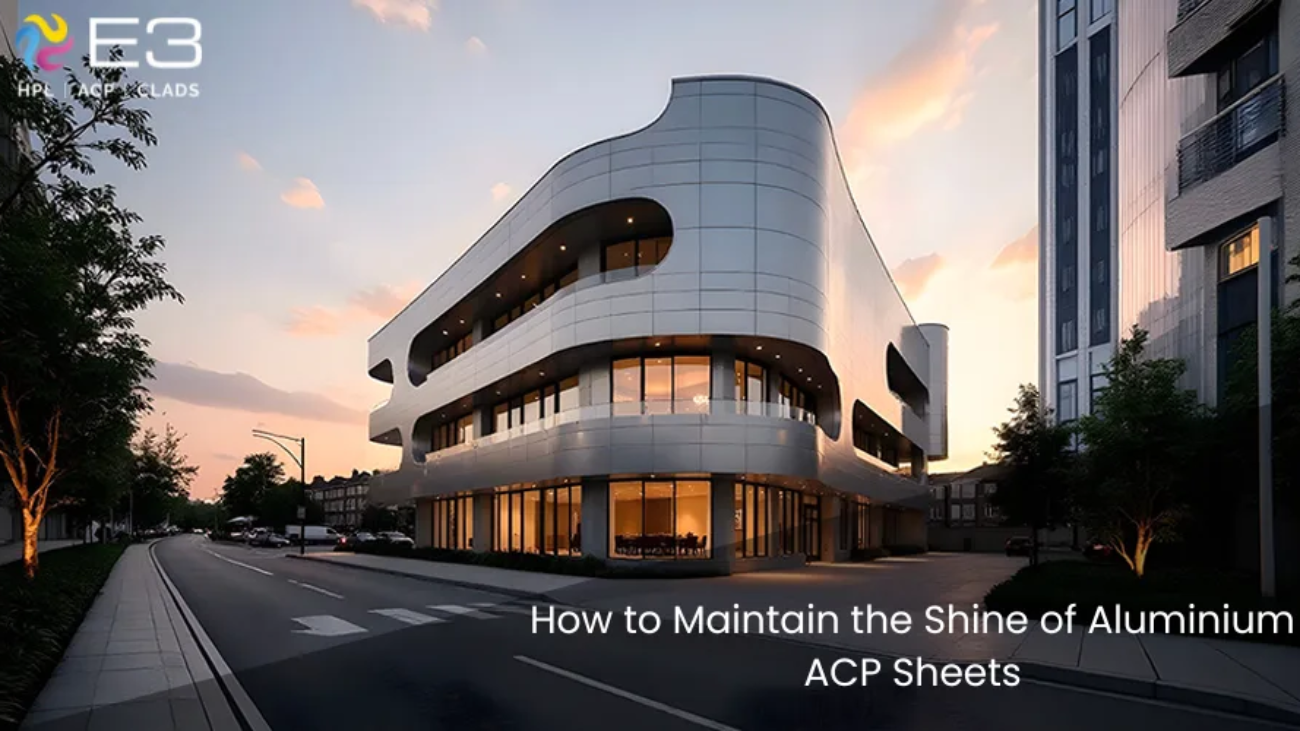

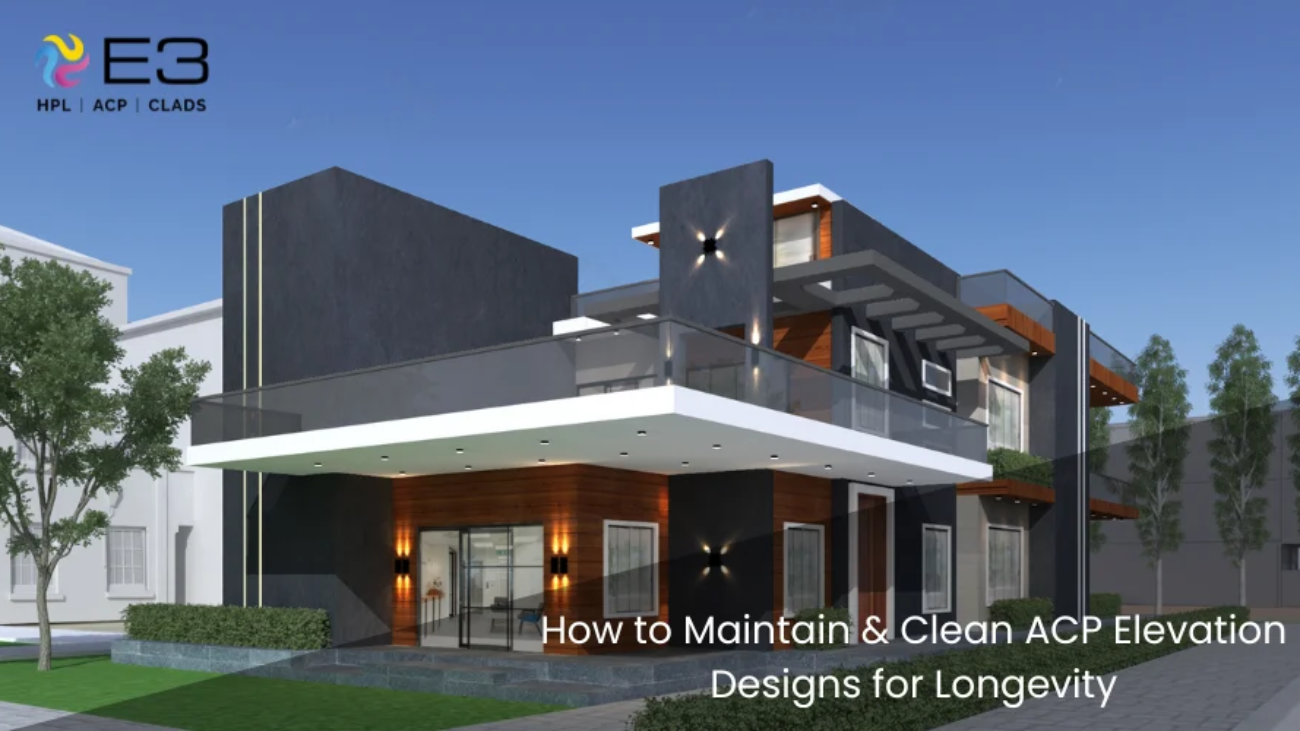

Typical Applications in Residential and Commercial Buildings

From stylish home decor to high-rise commercial building facades, ACP panels find use everywhere. In homes, they’re used for many applications. Commercially, ACP sheets can be found in exterior cladding, signboards, canopies, and shopfronts. Their capacity to resist weather exposure without losing their aesthetic appeal makes them a practical option for both internal and external use.

However, aluminium composite panel price can vary, and finding a seller with quality finishes under budget can be a task.

Why ACP is a Better Choice for Cladding

For exterior as well as interior cladding, ACP is preferred for a number of reasons:-

- Light in weight and simple to install

- Resistant to weather, UV, and corrosion

- Cost-efficient as compared to other cladding materials

- Available in a broad color and texture palette

- Agels with less maintenance

E3 Aluminium Composite Panels: Brand Overview

E3 is a top ACP manufacturer in India, renowned for innovation, quality, and design flexibility. With best-in-class manufacturing facilities and advanced technology, E3 provides ACP solutions that are at par with international standards. For interior applications in residential spaces or exterior uses in high-rise commercial buildings, E3 provides every panel to satisfy aesthetic and structural requirements.

Industry Reputation and Trust

E3, over the years, has established a strong brand reputation within the architectural and construction sectors. Supported by architects, builders, and home owners nationwide, we identify with dependability and contemporary style. Timely delivery, reliable product performance, and superior after-sales service have made us a go-to brand in the ACP industry.

Quality Assurance and Standards Followed

Quality is never compromised at E3. Every ACP panel goes through rigorous quality control testing for durability, color hold, and fire resistance. We maintain ISO-certified production processes and adheres to national and international safety standards.

E3 Aluminium Composite Panel Price: What Factors Influence the Cost?

A number of different factors determine the aluminium composite panel price. At E3, the cost includes the material and the performance, lifespan, and beauty of each sheet.

- The grade of aluminium employed and the core type—standard or fire-retardant—significantly influence the aluminium composite panel price. E3 employs top-grade raw material for safety, durability, and weather resistance. FR (fire-retardant) core panels are more expensive but give extra protection.

- E3 ACP sheets are produced in a range of thicknesses, from 3mm to 6mm. The thicker panels are more rigid and stronger, and are recommended for exterior facades. Of course, the thicker the panel, the more ACP panel price will be, as material consumption and performance increase.

- We provide a wide variety of textures—matte and gloss, as well as wooden and marble textures. This can also influence the aluminium composite panel price. Special textures or metallic coatings are available that add a new ACP panel rate but take the aesthetic value to another level.

- Custom-size panels, special colors, and branding prints can affect the cost. E3’s large color gamut and capacity to personalize panels for individual design requirements contribute to its value, providing value beyond normal options.

- With E3, you’re not merely paying for a panel—you’re making an investment in a trustworthy brand. The extended warranties, uniform quality, and reliable service increase the overall value. This robust brand guarantee merits the acp sheet price, making E3 a trusted option for both large projects and personal projects.

How to Connect with E3 ACP?

Connecting with E3 ACP is straightforward, offering multiple channels to suit your preferences. Whether you’re interested in their products, seeking dealership opportunities, or have general inquiries, here’s how you can reach out:

For detailed inquiries or formal communication, you can email E3 ACP at: acp@e3acp.com

To speak directly with their team for immediate assistance or information: +91 9310934090

You can also reach out through their official website by filling out the contact form: https://e3acp.com/contact-us/

Stay updated with E3 ACP latest products, news, and events by following their social media handles:

- Instagram: https://www.instagram.com/e3acpindia/

- Facebook: https://www.facebook.com/E3ACP

- Youtube: https://www.youtube.com/@e3groupindia

Final Thoughts

ACP sheet cost depends on many factors. E3 ACP provides panels that can transform your space and show that excellent design doesn’t have to break the bank. From premium textures, better durability, and diverse uses, E3 offers so much more than mere surface value.